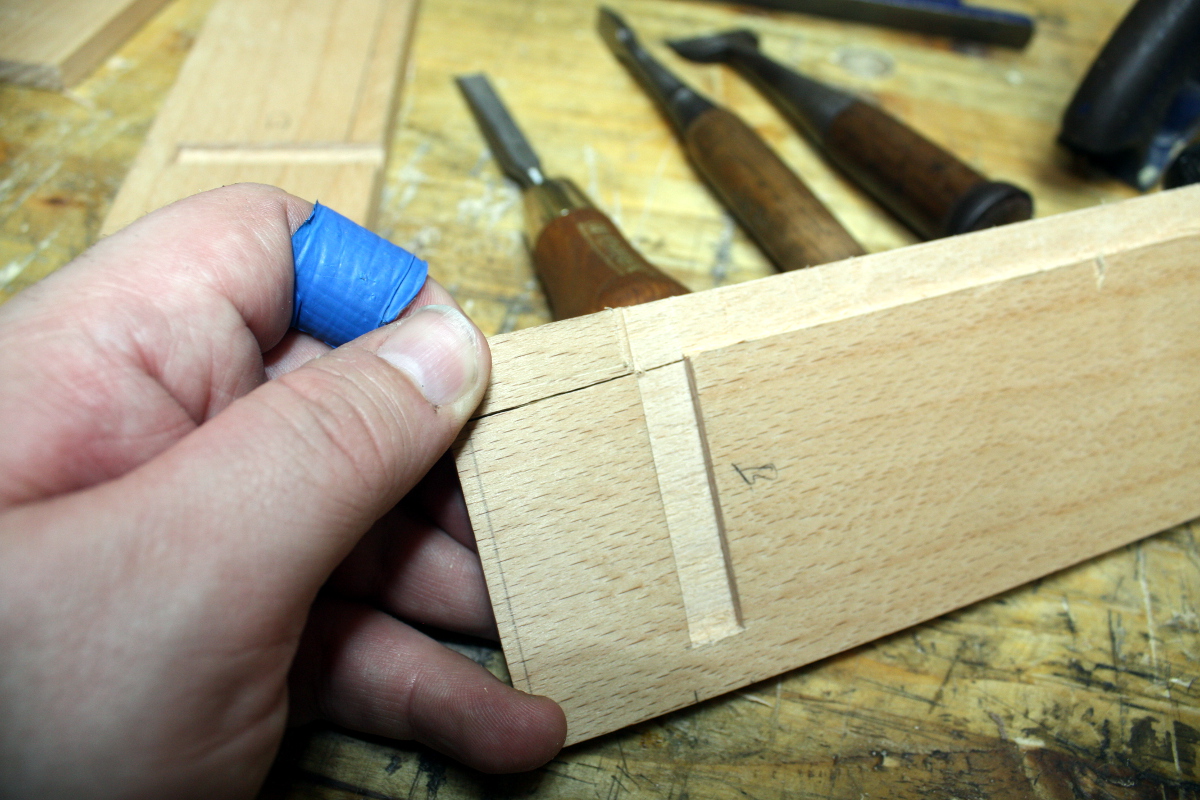

So, another housing joint to chop…

Giving the new chisel mallet a workout. So far, it’s working very well. Chopped the housing joints as per yesterday (had to take a pause to take the #08 to the edges in the vice, I’d missed a small bow in the edge so I wanted to correct that before marking out for the new joint).

All grand. Did a test assembly and everything fitted and was square. Excellent. Then thought about the back and decided to rebate it in, but with a stopped rebate (the client 😀 doesn’t want the back to extend all the way to the ground), so marked out for that and got out the #778 and suddenly realised that on one side (and of course, the side I’m starting on), the #778 is the wrong handedness. Bugger. So off with the fence and the rods and we attack it from the other side, treating the #778 like an old wooden rebate plane. Which is a pretty hairy routine – tilt it over on the inboard side, run the point of the blade along the knife line to dig its own reference edge, then drop the outboard side gradually to work down to a shallow but level rebate and then plane to depth… except that the stopped rebate bit means the plane isn’t of use for the last two or three inches. Bugger. Well, you can chop a rebate with a chisel…

Bloody complicated rabbit this. Starting to question the wisdom of the idea. And then on almost the last chisel chop getting the wall of the rebate vertical, the inevitable happened…

Well, feck.

Short crack, too thin for PVA or hide glue, don’t want to split it off and glue it back on, so… low viscosity superglue, your time has come! Held it gently open, and dropped in thin superglue until I could see it running all down through the crack and then clamp the crack shut and set aside overnight.

James Wright did a long series of tests on wood glue recently and CA glue (superglue) very surprisingly blew most of the competition away in several categories from strength to filling ability to shearing force and so on, so maybe this will work.

If not, I’ll break it off completely and reglue it with PVA and accept the surface defect, but hopefully it won’t come to that…

Tags: beech, CA glue, chisels, glue, hand tools, repair, superglue, Woodworking

As a stopped rabett is a kind of stopped groove, you might try this another time:

https://journeymansjournel.wordpress.com/2018/06/10/rocking-cradle/

Now I have to order the fence for the Veritas router I received three and a half month after ordering it. As there is no endangered species wood on the fence, I hope there will be no further problem.

Sylvain

I do use the router (an #071 or #722 depending on the size of the groove involved) for the last mm or so of rabbets and grooves, but it’s faster if I chop out the bulk of the waste with the chisels – the router’s more a finishing plane for me. And yeah, cites rules on exotics are a pain sometimes, but they’re for the best in the long run. Beats the victorian’s method (clear-cut entire species out of existence so none of us get to play with lignum vitae or mahogany or rosewood anymore 🙁 )

It seems Veritas was in someway taken by surprise or didn’t plan ahead. I don’t mind having mundane wood for the handles of my tools.

I agree. I am for the protection of the biodiversity (wood included).

Sylvain