So no major new projects taken on yet, I’ve been tidying away some new toys and getting the shed back to a working state instead. For example…

I now have two pairs of hollows and rounds (4’s and 6’s) as well as a 7 hollow, the reeding plane and a spare 6 hollow. According to Mouldings in Practice that’s all I need to start off with for the scale of stuff I build. A pair of 2s and 8s would be the next on the list if this works out. I don’t like this storage solution though; you don’t really want to have a moulding plane tip over and fall on your head from two feet up. I’ll build a rack for them seperately later .

I also wanted to increase the final grit of my sharpening setup (before the strop), and while waterstones seemed the obvious choice, they’re messy as all get-out. Also, the way I work I don’t have a huge amount of time in the shed so waterstones that you don’t have to soak for 15 minutes before sharpening would be mandatory (whether that be solved by storing them in water or having the shapton type that you can just squirt water onto and get going), and those are not that cheap. But if you want 20,000 grit, they’re you’re only real choice.

Thing is, okay, I do have a japanese chisel or two but most of my work isn’t done with A2 or PM-V11 steel or anything that esoteric, so waterstones aren’t really mandatory; and diamond plates will go up to 8000 grit if you buy from DMT. Okay, the 8000 grit one isn’t cheap, it’s nearly ninety quid, but the things last for a decade and they’re very low fuss, so I cried once and bought one.

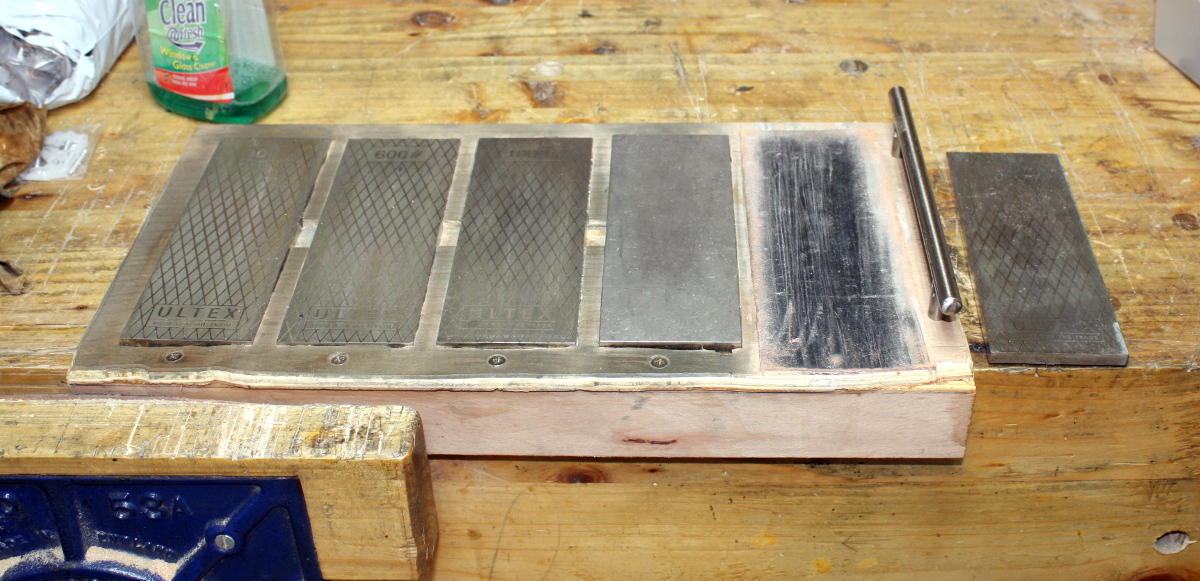

Swapped out the 1200 grit Ultex and in went the 8000 grit DMT. The Ultex went into just-in-case storage. I’ve only sharpened the new japanese chisel on the DMT so far (it’s been a quiet week) but for such a fine grit, it visibly cuts quite surprisingly well.

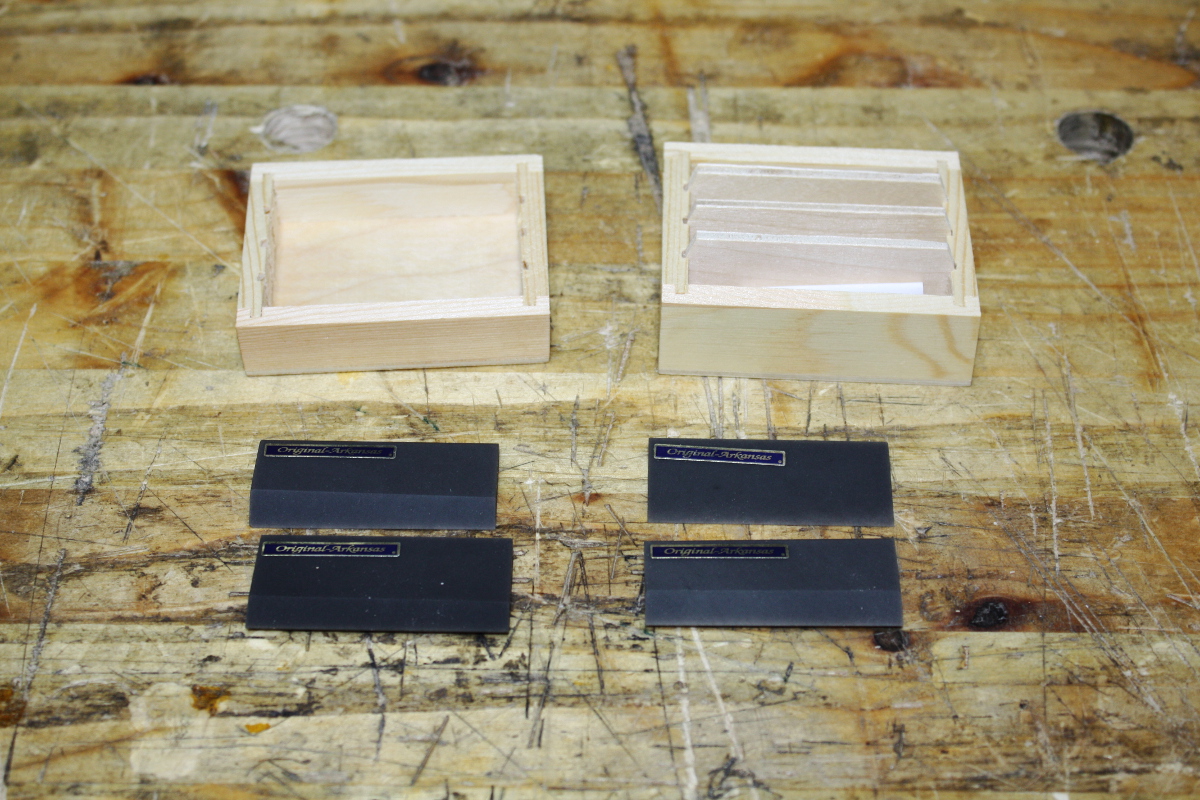

Speaking of sharpening, I needed something for the inside of the gouges, so some black arkansas slipstones got bought along with the DMT. Seem nice enough, and not too expensive. Not used yet though….

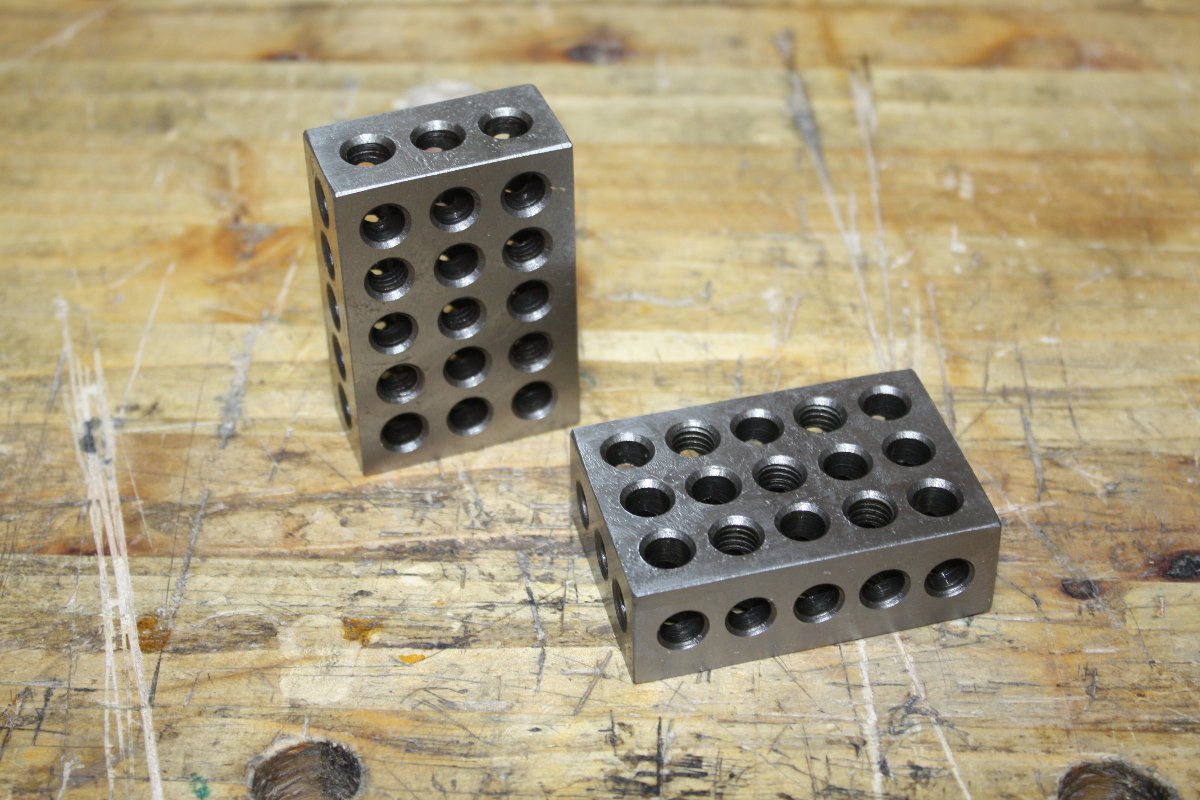

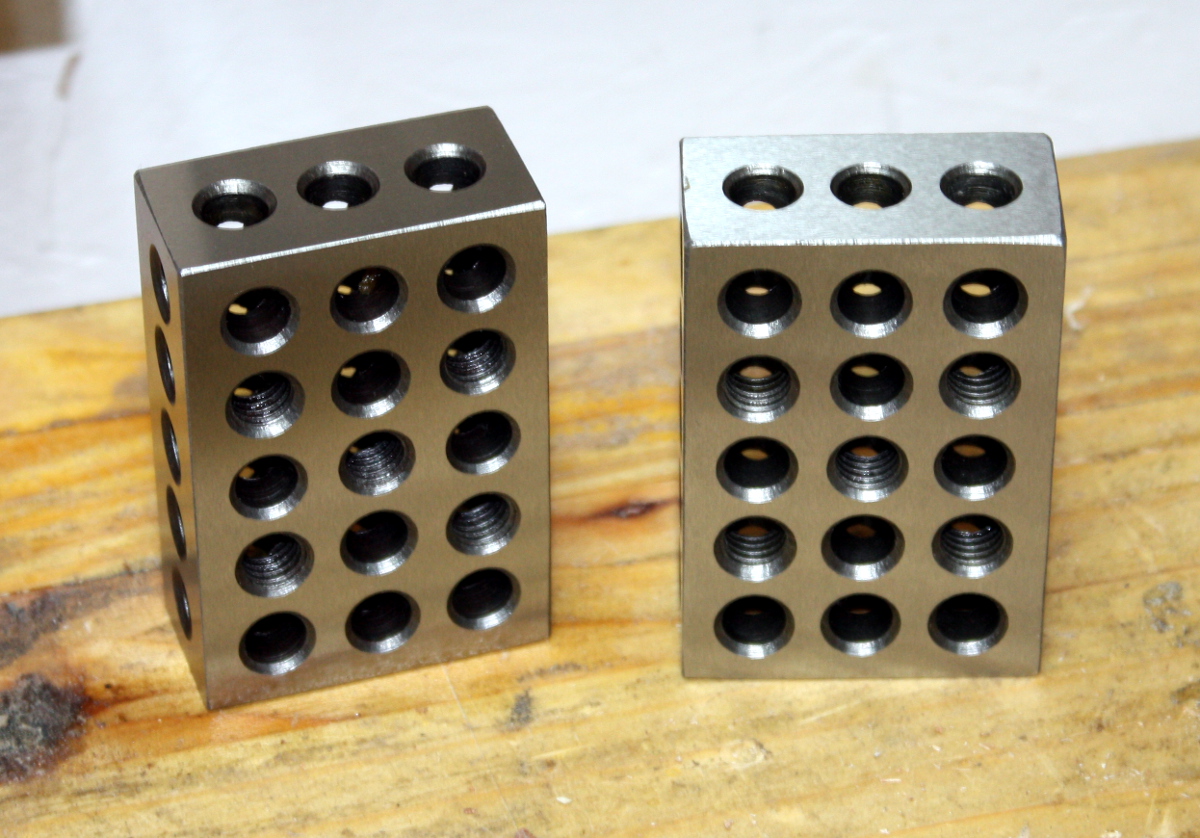

And I got some 1-2-3 blocks. I’ve been meaning to get some for a year or so now. For woodworking they’re not as useful as they would be to a machinist, but not having to measure off 1, 2 or 3 inches, being able to set up the bandsaw or fences with right angles, clamping odd things, they’ll be bloody handy for that I suspect. Need to put a mount on the wall for them (I suspect a pair of dowels in the nonthreaded holes will suffice). Pain in the fundament cleaning all the storage grease off them though, but when you do, they’re nice and shiny…

This radius cutter isn’t new, I’ve had it for 18 months or so but I haven’t used it (look, life gets complicated sometimes, okay? 😀 ). I finally got to watch the line-and-berry video this week and dug this out, I have an idea for a project I want to use it on. More to come but I need to make a tool or two first…

One tool down, another to go yet. I also need to find a source for 1/32nd holly veneer, which in Ireland seems more difficult than expected.

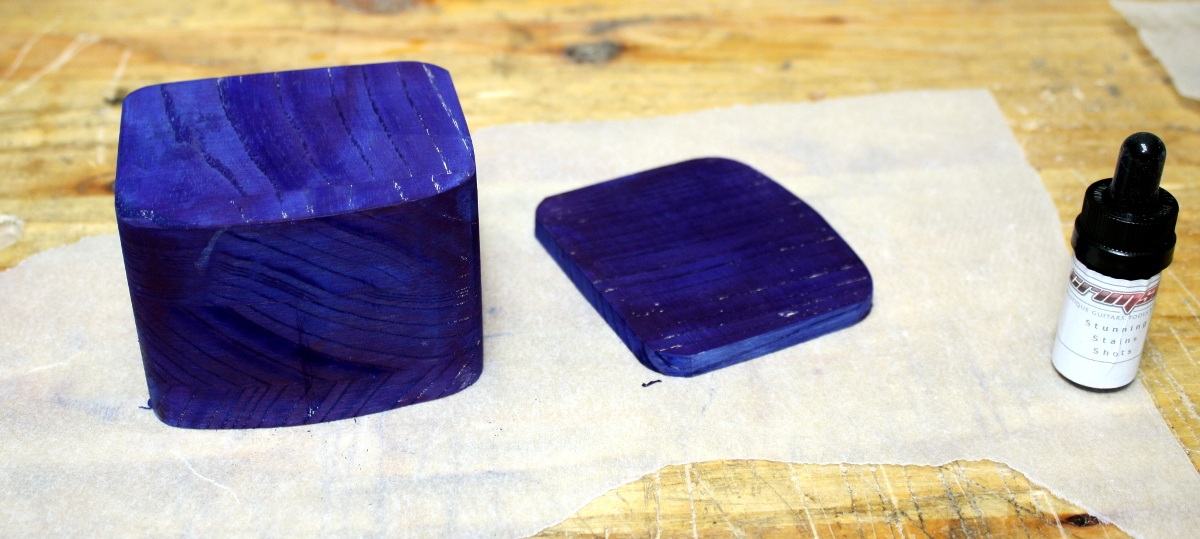

Wanted to finish this up as it was sitting around (it’s planned to be a salt box). It’s a bit… drab as is though. If only I had something to jazz it up a bit…

*hehehe*

Well, that was… intense. Left it overnight, sanded lightly to knock back grain and re-stained it today and gave it a coat of spray laquer.

It’s not terrible, but it’s a bit more blotchy than I was hoping for. Hmmm….

Also, I had another bandsaw box waiting to get a hinge and get finished so I wrapped that up as well but with just a coat of BLO…

I have no idea what it’s for by the way, I just wanted to use up a scrap and play with making a brass hinge (learned I can’t really do it in my shed unfortunately, I’d need a proper anvil I think. Oh well).

I’m almost done with the last of the tidying up at this point. Just need to sort out this guy and that’s the last big task I think. There are other things, magnetic rails and move some tools about and other small stuff, but this one’s the awkward one I think…

Tags: bandsaw box, poplar, sharpening, shed, Woodworking, Workshop

Those plastic cyclone bins don’t work so well, do they. I grabbed one from the place named after a South American river with a step in it, then bricklaid a ring to reinforce it from imploding. Works well so far. If that one starts crushing, I’ll bite the bullet and get the metal canister.

I found once they go raisin shape, it takes less and less vacuum to repeat the process.

Yup, once you pop, you can’t stop 😀

For the new one, I’m putting a pressure relief valve in the top (nothing fancy, just drill a hole, have a dowel-and-plate plug the hole from inside and have a spring holding the plate against the inside of the drum head. When the vacuum exceeds the spring force, down goes the plate, in comes air from outside, stops the barrel collapsing. That, and the extra strength from the smaller size, might be enough to keep it intact.

…maybe 😀

For future reference, I bought an Eagle 1610MB drum and you can see where the side is stepped – that’s where I put the reinforcement ring inside. It raisined without the ring but has been fine since. I use a 30 gallon liner to make emptying easier.

Good luck.