Wristrest

So I’m still cleaning down the shed from the cot (finally got all the shavings under control…) but yesterday an officemate (hi Gary!) was looking at MassDrop (think “what to get for the rich geek who has everything” with a pricetag to match) and specifically at a wrist rest. For those who don’t type all day, it’s something to rest the wrist on while typing:

If you type all day every day like a lot of software engineers do, this is a pretty necessary thing or you wind up with carpal tunnel syndrome. I’ve had that, it’s not fun (it’s why I’ve used kinesis ergonomic keyboards for twenty years).

So the specific one Gary was looking at was wooden, and nice enough if a bit simple:

I mean, it’s not some gel-filled cushion, it’s not articulated, it’s just a shaped plank of wood. Walnut maybe? Fourteen inches wide (the width of a MacBook Pro) and about three inches deep.

They’re charging $95 for it (or they were, it’s not for sale any longer). I nearly choked on my coffee. I told him that was insane, that it was a lump of wood and not worth it and that I could knock that up in my shed in twenty minutes from an offcut. So he said “prove it”.

That’s how I keep getting myself into these things. You’d think I’d have learned by now.

So I go home, I find a piece of walnut offcut (in this case it was a length intended to be part of the cot frame but a bad rip cut and a waney edge made it unusable for that), I cut out a 14″x3″ piece from it (I don’t even take the time to lay it out) and skim plane it to clean off the rough-cut furriness. Then I plane one face and edge to square, and shoot the ends square from that. I don’t bother with the other edge or face because they’re going to get shaped anyway. And I cut the corners curved on the front using my new toy that just arrived from Dictum today:

Well, I have a project or ten in mind that will involve dovetails and I want to try sawing out the waste on the pinboard instead of chopping it out because that took a bit longer than I thought it would on the cot drawer. I need a better place for it to live though…

I also need to finish tidying up, and one of the next shed projects is tool storage. But for now…

And from there, I get out the spokeshave and round over edges and I use the jack plane to cut a quick chamfer on the front edge and then go over everything with the spokeshave again to get it all nice and smooth, and I hit the ends with some sandpaper for a few seconds to get the last little bits around that knot on the left front side.

Total time from start to here was about 25 minutes or so (I was faffing about a bit with the new fretsaw). With machines, that’s two tablesaw cuts, two mitre saw cuts and a run-around on a router table, so maybe three minutes?

It needed a little finish and I had the dregs at the bottom of the shellac jar to hand so…

One coat on by brush, then in for a cup of tea and a bit of Richard Maguire’s latest sharpening video while it dried. Then out to the shed again, some steel wool to knock back the first coat of shellac and rag on a second. Back to the house for more tea and Maguire, and half an hour later I take the offcut piece of felt I had from lining the cot drawer and cut a small piece out of that and spread it and the underside of the rest with contact cement from the end of a tube left over from putting leather on the bench vice jaws.

Let that get tacky for ten minutes, then press the two together and trim the excess. And then a final coat of briwax on top for the shiny.

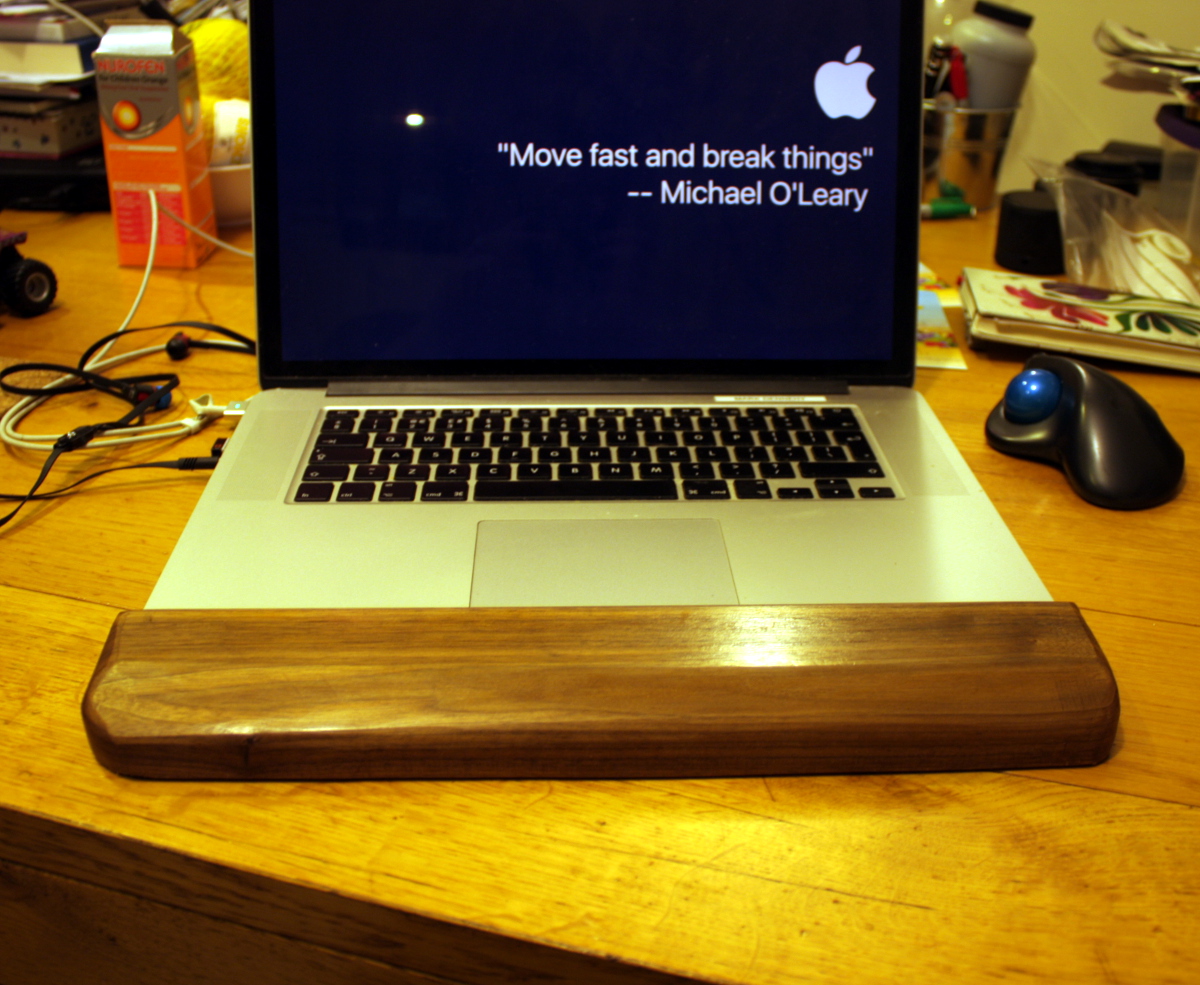

By this point I realise I’m foostering so I draw a line under it and wander back in from the shed. Total work time is about 30-35 minutes (with something like 90 minutes of waiting on finishes while watching videos and drinking tea in there too). And the test fit worked:

And it doesn’t just work on my laptop, it works in production*:

So $95 versus €2. Hell of an exchange rate, even when you count the three minutes it’d take to make with machines, labour, marketing and so on.

*That’s a joke for the other IT people btw.